American Soy

Maintenance Technician

Brief Summary

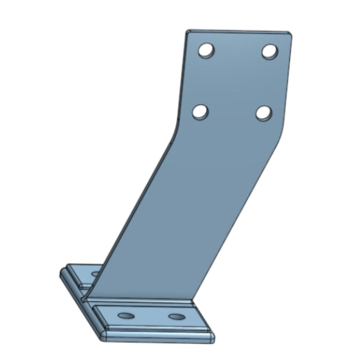

To address a mechanical failure, I leveraged CAD design software, CNC machining, and welding to modify a failing component. The original part suffered from structural weaknesses, so I redesigned it in SOLIDWORKS, incorporating a reinforced, thicker bottom to improve durability and prevent breakage. The process involved 3D modeling, stress analysis, precision CNC machining, and welding, ensuring a strong and reliable connection.

Business/Organization Outcome

This redesign aligned with the company’s goal of reducing costs by eliminating the need to purchase expensive replacement parts from a supplier. By reinforcing the failure-prone area, the updated component extended the part’s longevity, minimizing downtime and maintenance costs. The solution provided a more durable, cost-effective alternative to frequent part replacements, contributing to increased operational efficiency.

Personal Outcome

Through this project, I strengthened my skills in failure analysis, design optimization, and hands-on manufacturing techniques. I gained valuable experience in applying engineering principles to real-world problems, reinforcing my ability to develop practical, cost-effective solutions. This experience also deepened my understanding of structural integrity, material properties, and precision fabrication.